Geology

The deposit is currently known over a strike length of more than 500 metres with an average width of approximately 150 metres. The depth extent of the deposit is not known with relatively minor deeper drilling having encountered mineralisation to depths of approximately 300m below surface.

The mineralisation at Great Pyramid is formed by closely spaced sheeted northeast trending, cassiterite (SnO₂) bearing veins associated with silicification and sericite-pyrite alteration. The deposit style and regional comparisons suggests that a tin-fertile granite exists at depth below the deposit, however this has not been encountered and the deposit is open at depth.

Historic Exploration

Drilling commenced at the deposit in 1964, with BHP drilling shallow percussion holes and one diamond drill hole. Between 1969 and 1974 Aberfoyle Tin drilled a series of close spaced shallow percussion holes and diamond drill holes. The Tasmanian Mines Department drilled four diamond holes in the 1970’s and Shell drilled a further two diamond holes in 1983. The final drilling on the project was in 2018 with previous owners TNT Mines drilling a single diamond drill hole.

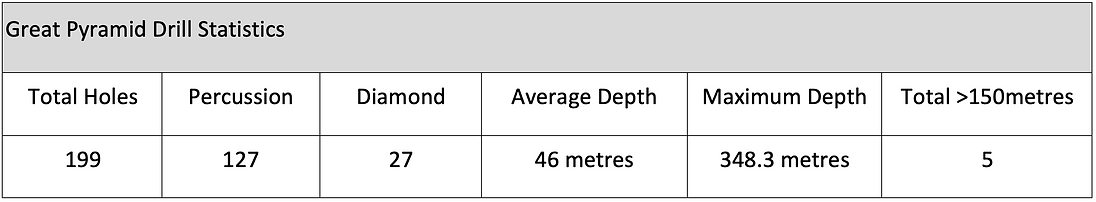

A total of 199 holes have been drilled at the deposit with an average depth of 46m. The maximum hole depth is 348.3 m and only 5 holes deeper than 150 metres have been drilled.

The deposit’s nature and extent are not constrained laterally or vertically, and the deposit is considered open for extension in all directions.

Prior to TinOne Resources Inc., no modern geophysical methods had been conducted.

Resource

Mineral Resource Estimate

The MRE was prepared by Mining Associates Pty Ltd. in accordance with Canadian Institute of Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves adopted May 19, 2014, and in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”). The effective date of the MRE is August 31, 2023.

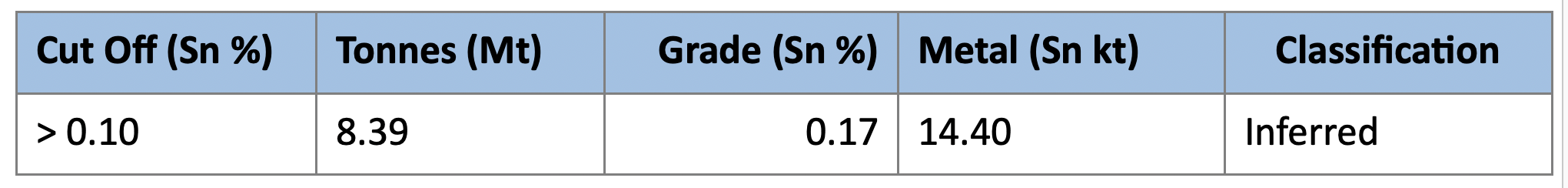

Table 1. Great Pyramid Project tin deposit inferred Mineral Resource1,2,3,4,5

- Near surface mineral resources are reported at a Sn cut-off grade of 0.10% inside a domain based on geology and grade and considering a Sn price of US$24,978/t and 80% recovery for tin.

- Mineral resources are reported within a conceptual pit shell.

- Mineral resources are not mineral reserves and do not have demonstrated economic viability.

- All numbers have been rounded to reflect the relative accuracy of the estimate.

- Discrepancies may occur due to rounding of values.

Please click here to view the full MRE Report.

Mineral Resources Estimation Methodology

The MRE model is informed by 40 diamond core holes, 16 reverse circulation (“RC”) holes and 159 percussion holes. Thirteen core holes (from surface or pre-collared) and 16 RC holes were drilled by TinOne in 2022 (see the summary in the Company’s news release dated February 2, 2023), including three holes that were abandoned within 42 m and redrilled. One hole was attempted three times before being abandoned as the drill string could not penetrate an historic adit. Additional drilling was carried out by previous property owners in 1965, 1970 and 1980-1983. Of the 214 drill holes, 193 holes for 13,074 m were used to delineate the MRE. The 1965 percussion holes were rejected due to variable sampling and assay quality. Drilling covers a total area of approximately 600 m in a northwest direction and a maximum of 300 m in a northeast direction. The deepest hole reached a depth of approximately 400 m below surface, although most open-hole percussion drilling reached depths of less than 50 m.

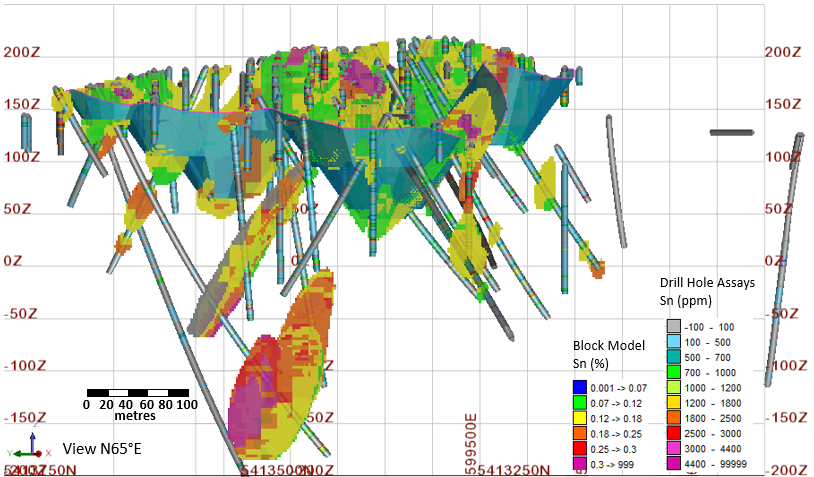

Figure 1. Oblique View of the Great Pyramid Project tin deposit showing the MRE block model, conceptual pit and near-resource expansion targets at depth.

Historical shallow vertical open-hole percussion drill holes were drilled on a regular grid at a spacing of approximately 30 m by 15 m covering the entire outcropping area of mineralization. Other drill holes are at an irregular spacing, with some oriented to intersect stratigraphy rather than mineralization. The qualified person is of the opinion that the current drill pattern for the Great Pyramid Project is sufficient for the estimation of mineral resource for a sheeted vein style deposit.

A block model was constructed to cover the entire extent of the mineralized domains. Tin grades for each block were estimated by ordinary kriging using Geovia’s Surpac software.

The MRE has been classified as an inferred mineral resource in accordance with the CIM (2014) definitions as incorporated in NI 43-101. Classification is based on the confidence levels of key criteria such as geological continuity, geological domaining, drill hole spacing, structural data, and geostatistical measures.

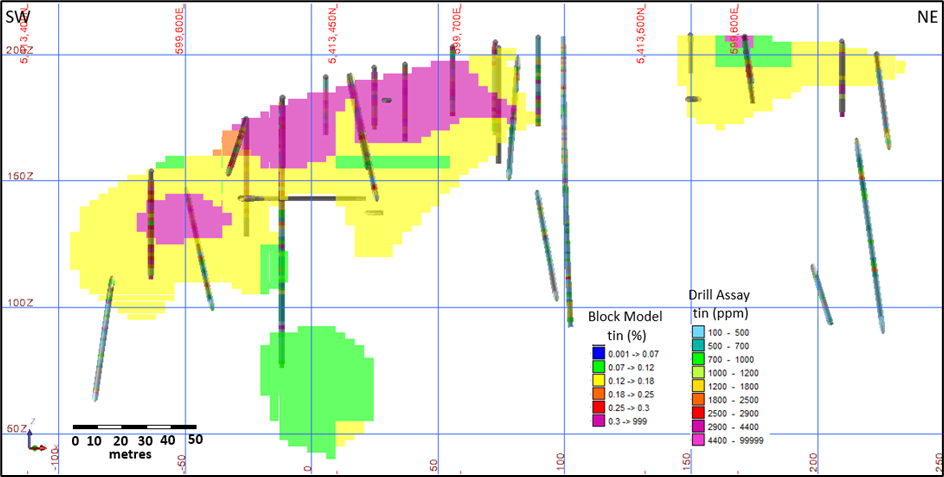

Figure 2. Oblique section (200) showing tin block grades and drill hole grades.

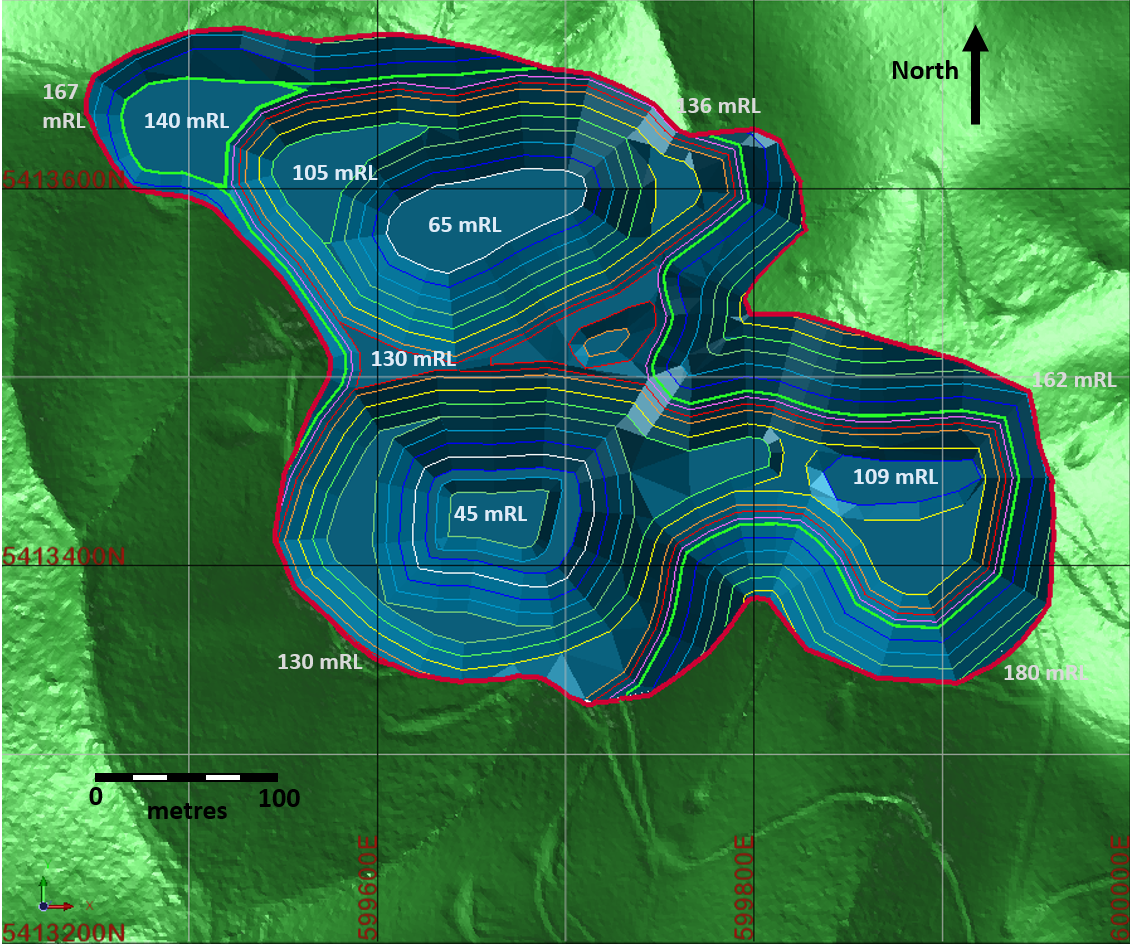

Figure 3. Plan View of Great Pyramid Project conceptual pit shell used to constrain the Mineral Resource.

Reasonable Prospects for Eventual Economic Extraction

The predominant tin bearing mineral is fine grained cassiterite. Mineralization is near surface and may be extracted using conventional open pit mining methods. Concentration of cassiterite to a commercially acceptable concentrate of 55% Sn could be achieved by a combination of size classification, gravity separation and/or sulphide flotation.

The following assumptions are some of the considerations in evaluating reasonable prospects for eventual economic extraction (“RP3E”). The RP3E test does not demonstrate economic viability and does not qualify as a reserve. A metal price of US$24,978/t and a metallurgical tin recovery of 80% is assumed based on preliminary test work undertaken in the 1980’s. The conceptual pit was created with a wall angle of 55°, no berms or ramps are included in the conceptual pit shell, and the implied strip ratio is very low at 1.12:1 waste:mineralization. Total costs per tonne for mining and processing is assumed to be $18.53/t processed and cost assumptions were compared to the Taronga Tin Project PFS. Portions of a deposit that do not have RP3E have not been included in the mineral resource estimate.

Geological Interpretation and Mineralization Controls

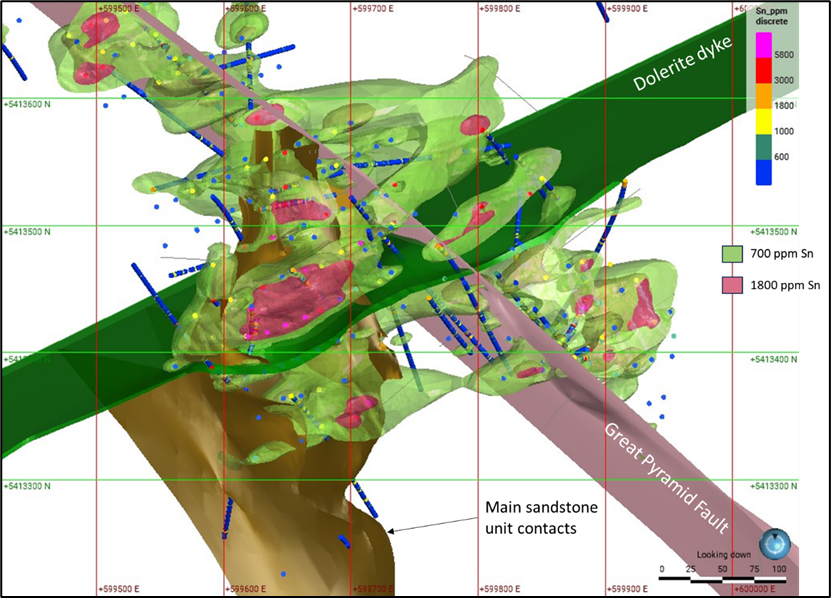

Mineralization at the Great Pyramid Project is hosted within northeast- to east-northeast trending and steeply northwest dipping zones of sheeted, narrow quartz veins that cross-cut northwest-trending stratigraphy and folding. It is recognized that mineralized veining and fracturing is generally of higher density within quartzite/sandstone units and an initial attempt was made to define the contacts of the sandstone units as 3D surfaces to assist with estimation domaining. Two nested grade domains with cut-offs defined by natural breaks in sample statistics were modelled using Leapfrog™ software: low-grade (LG) >700 ppm Sn and high-grade (HG) >1800 ppm Sn.

Figure 4. Plan View of Geological-Mineralisation Model.

TinOne Resources Inc. Exploration

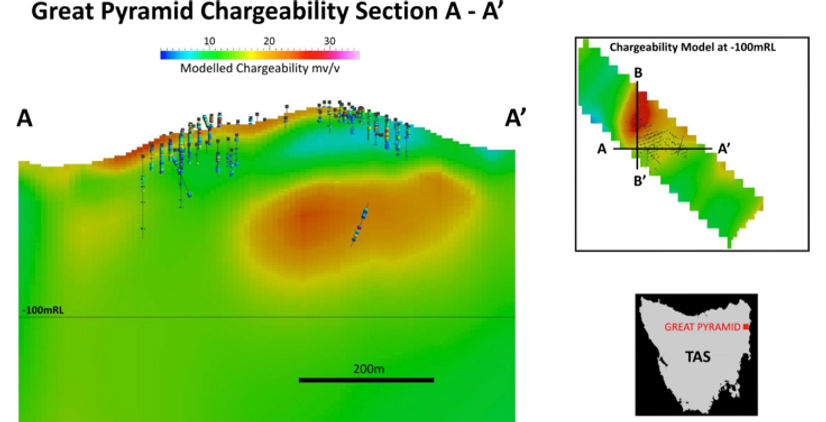

The principal work undertaken by TinOne Resources Inc. has been the collection of a trial 3D IP-Resistivity survey. No previous modern geophysics has ever been conducted on the project and geological observation of quartz-pyrite alteration and veining suggested to Gondwana that IP-Resistivity may be an applicable technique.

The trial survey was conducted on north westerly oriented lines and was highly successful in confirming that known mineralisation is associated with a strong chargeability response. Furthermore, the survey was highly encouraging in defining three significant targets for follow up. These targets include a major combined chargeability and resistivity target beneath and to northeast of the current resource and additional strong chargeability anomalies to south and southeast. Two of these targets are undrilled and the third has a single drillhole. The northeast and southeast targets extend to the limits of the current survey and hence are entirely open.

Exploration Plans

TinOne Resources Inc. plans to execute systematic exploration utilising modern techniques. This is likely to include:

- Additional IP/resistivity

- Reverse Circulation and diamond drilling within and below the current resource

- Reverse circulation and/or diamond drilling of IP/resistivity targets

Qualified Person

The scientific and technical information in this website has been prepared in accordance with the Canadian regulatory requirements set out in National Instrument 43-101 (Standards of Disclosure for Mineral Projects) and reviewed and approved by Dr Stuart Smith as a Qualified Person as defined by NI 43-101 (the “Qualified Person”). Dr Smith is a Technical Adviser to the company.